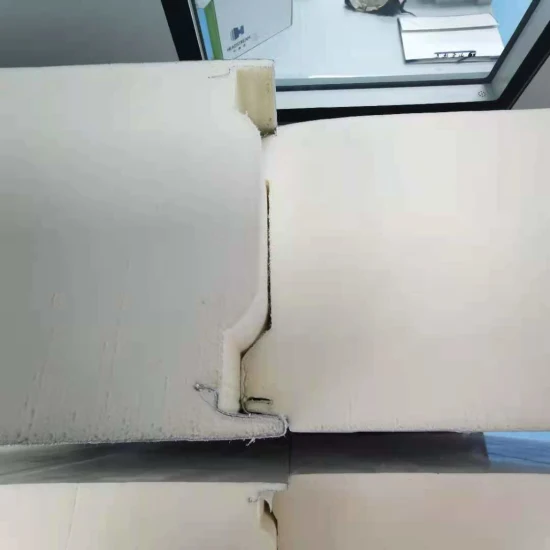

50mm/75mm/100mm/150mm/200mm/300mm EPS/PU/PIR/PUR/Polyurethane/Rock Wool Structural Insulated Sandwich Panel for Internal and External Wall

Description

Basic Info

| Model NO. | PIR/PU/PUR sandwich panel |

| After-sales Service | Raphic Design, 3D Model Design, Total Solution |

| Warranty | More Than 10 Years |

| Feature | Fireproof, Metal Panel |

| Fire Rating | 1 |

| Certification | ISO9001 |

| Customized | Customized |

| Width | 1000/1120mm |

| Length | <11.8m |

| External Plate Thickness | 0.4mm-0.7mm |

| Internal Plate Thickness | 0.4mm-0.7mm |

| Density | 40kg-43kg |

| Steel Plate Color | Ral |

| Certificate | CE/ISO/FM |

| Transport Package | by Sea |

| Specification | 50mm/75mm/100mm/120mm/150mm |

| Trademark | N/M |

| Origin | Shandong, China |

| HS Code | 7326901900 |

| Production Capacity | 100000 Meter/Meters Per Month |

Product Description

Polyurethane sandwich panel is the best heat insulation and energy saving material recognized in the world today. It has been widely used in large industrial plants, exhibition halls, gymnasiums, cold storage, purification workshops, animal husbandry, edible fungi and other industries. Polyurethane, as one of the most excellent insulation materials in the insulation and energy saving market at present, makes polyurethane hard foam products more and more widely used in building energy saving and heat preservation with its unique advantages. Building energy saving will become the main application direction of polyurethane hard foam in the future.

| Item Panelsize |

| Panel size width 500-1120mm |

| thickness 30-250mm |

| length <11.8m |

| Skin sheet material color coatedsteel/stainless steel/ gavalume steel |

| thickness 0.4-0.8mm |

| paint type PE/HDP/SMP/PVDF |

| PIR fireproof grade B1(Oxygen index>30%) |

| percentage of close area ≥90% |

| water absorption ≤3% |

| thermal conductivity 0.018-0.021 |

| applied environment -60C~+100ºC |

| PS:The weight of the plate is calculated accordin to the thickness of 50mm |

Coefficient of thermal conductivity among the0.0190-022w/m.k between 25ºC(C),which is the lowest coefficient of thermal conductivity for the practical application of heat preservation material.Continuous foaming technology,using high pressure foaming uniform density,closed pore structure of small bubble hole,bubble hole density can be up to200000/cm3,obturator rate is as high as 97%above,bibulous rate is extremely low,which can effectively prevent water vapor permeability,so as to exert its excellent heat preservation and heat insulation performance.Good fire resistance

PIR rigid foam has excellent fire resistance as the coking protective layer will be formed during the combustion process,which will not melt and drip like EPS foam and XPS foam.The flame retardant property can be further improved when composite with metal plate.Combustion performance reached national standard 8624-2012 B1 grade.Advanced cyclopentane technology

The use of fluorine-free raw materials for one-time high pressure foaming,no chlorofluorocarbons,zero greenhouse effect,no pollution to the environment,in line with the international ozone layer convention and European environmental standards.Unique airtight technology

The unique panel type airtight structure technology makes the adjacent plate joint insulation laye rmore organicallyintegrated,greatly improving the airtight performance,more suit ablef or airconditioning storage.Energy saving-consumption reducing-environment protection

The selection and processing ofpolyurethane panel,are in strict compliance with national and industrial environmental standards.In the process of use,it is not easy to breed bacteria and parasites,adapt to the cold chain industry in a variety of complex situations and stringent environmenta requirements.The cold storage insulation system with proprietary panel type airtight structure technology can integrate the cold storage into an organic whole,achieving absolute airtight,saving energy consumption by 30% and greatly reducing operating costs.Easy and quick installation

The panel is prefabricated in the factory,and the installation system design is mature to meet the all -weather construction requirements,shorten the installation cycle,and reduce the labor cost and material loss.Packaging & Shipping

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

FAQQ1.Are you a manufacturer or a trading company?

A: Yes, we are 100% professional manufacturer.Q2.Which delivery terms do you support?A: EXW/ FOB/ CFR/CIFQ3.How about your delivery time?

A: It usually takes 20 days to receive your deposit. The specific delivery time is determined by the quantity of products you ordered.Q4. what's the payment term?

A: T/T is 30% of the deposit and 70% before delivery. Before you pay the balance, we will show you the photos of the product and packaging.Q5. What is your sample policy?

A:1. We can produce according to the samples you provide.2. If you need to send samples by post, we can provide them, but the customer must pay the express delivery fee.Q6: What is your packaging standard?

A:All the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.If you have requirements, we can also manufacture iron pallet packaging.Q7: Do you check all your goods before delivery?

A: Yes.Before the product leaves the factory, we must carefully check all aspects, and after confirming that there is no problem,proceed with packaging.Q8: How to establish a long-term and good business relationship with us?

A:1. We maintain excellent quality and competitive prices to ensure that customers benefit;2. We respect every customer and treat them as our friends, no matter where they come from, we sincerely do business with them and make friends.

Our Contact